About Shandong Hongjia Food Company

About Shandong Hongjia Food Company

January 13, 2026 – Building on the on-site product inspection conducted at the R&D workshop yesterday, Mr. Zhao, General Manager of Hongjia Food Co., Ltd., today followed up with targeted suggestions for product optimization and personally supervised a new round of in-depth product testing. Focusing on the company's flagship Pre-Marinated Snakehead Fish Fillets, the testing included three key quality indicators: pre-cooking weight, post-cooking weight, cooking yield rate, and the number of fish fillets per pack. This proactive follow-up and iterative testing fully demonstrate Hongjia Food's rigorous pursuit of product quality and its commitment to building a closed-loop quality control system.

As a market-leading product, Hongjia Food's Pre-Marinated Snakehead Fish Fillets have always been positioned as a benchmark for quality and safety in the processed aquatic product industry. Yesterday's on-site inspection by GM Zhao identified potential areas for refinement in product consistency. To ensure that every detail of the product meets the highest standards, GM Zhao promptly organized the R&D and quality control teams to formulate optimization suggestions and launched a follow-up testing plan, emphasizing that "quality improvement is an iterative process; only by continuously verifying and optimizing can we live up to consumer trust."

During today's follow-up work, GM Zhao first put forward specific optimization directions based on yesterday's inspection results. He pointed out that while the product quality meets the national and industry standards, there is room for improvement in the consistency of cooking yield rate across different batches. He required the team to adjust the pre-processing parameters of the fish fillets to further stabilize the water retention capacity during cooking, ensuring that consumers can enjoy consistent taste and weight performance every time they use the product.

Subsequently, under the supervision of GM Zhao, the quality control team carried out a comprehensive testing process for the Pre-Marinated Snakehead Fish Fillets. Unlike routine inspections, this round of testing adopted an expanded sampling scope, covering 10 batches of products from different production shifts to ensure the representativeness of the test results. The testing process was carried out in strict accordance with the standard operating procedures:

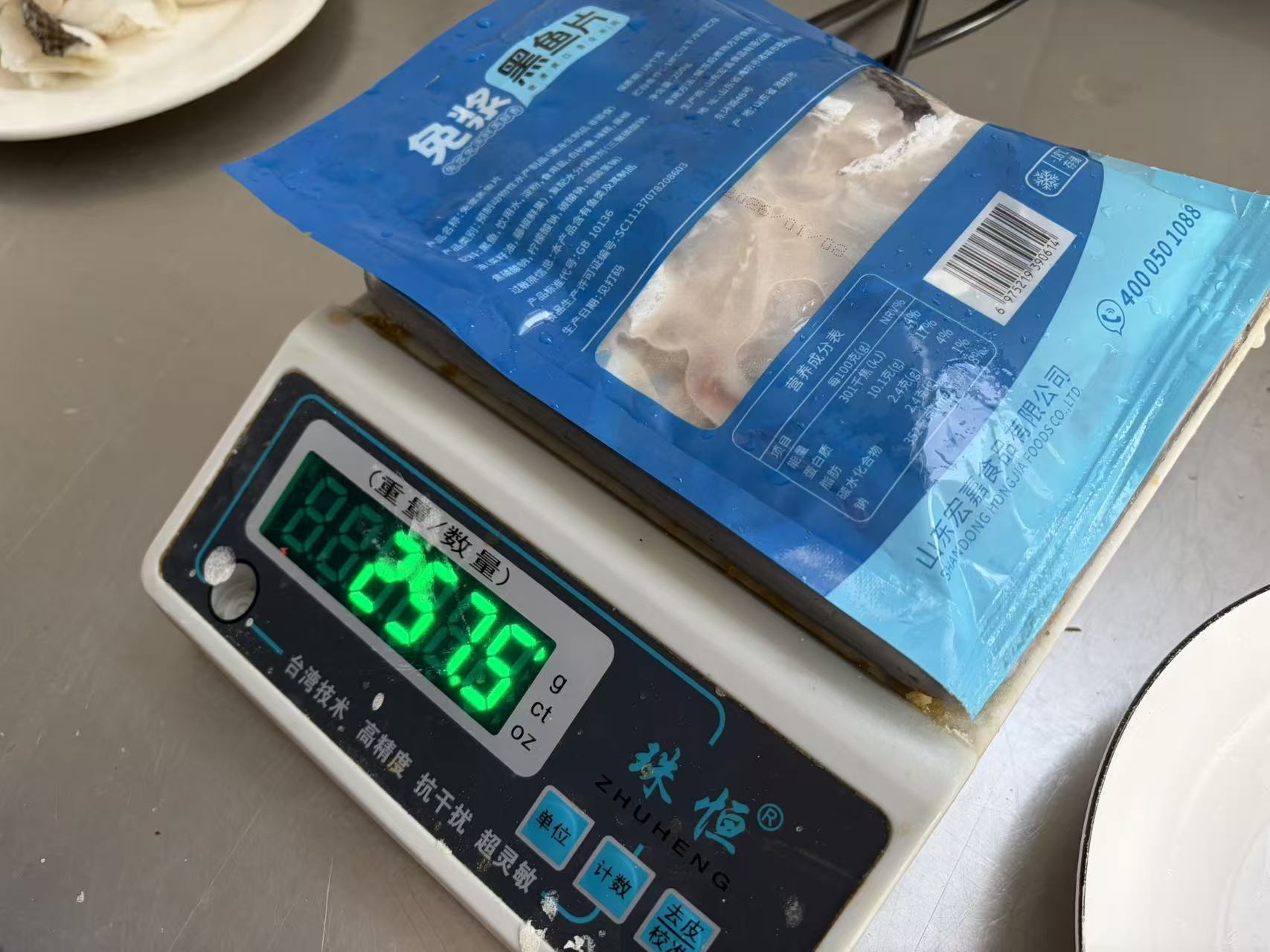

Pre-cooking and Post-cooking Weight Verification: Each sampled fish fillet was accurately weighed before cooking, and then cooked under standardized temperature and time conditions (simulating the common cooking methods of home consumers and catering businesses). After cooking, the weight was measured again to calculate the weight change and cooking loss rate.

Cooking Yield Rate Calculation: Based on the pre and post-cooking weight data, the team calculated the cooking yield rate of each batch in detail. GM Zhao emphasized that the cooking yield rate is a key indicator reflecting the product's water retention capacity and texture; maintaining a stable yield rate between 85% and 90% is crucial to ensuring consumer satisfaction.

Per-Pack Fish Fillet Count Recheck: On the basis of routine counting, the team increased the sampling ratio to 5% of the total output of each batch, manually verifying the number of fish fillets in each pack to eliminate any possibility of insufficient quantity due to manual operation errors.

During the testing process, GM Zhao closely observed every link, inquired about the test data in real time, and discussed with the team how to adjust the production process according to the preliminary results. He stressed that "every test data is a guide for optimization; we must treat every decimal point with a rigorous attitude to ensure that the product quality is stable and reliable."

The preliminary results of the follow-up testing show that the overall quality of the Pre-Marinated Snakehead Fish Fillets is excellent. The cooking yield rate of all tested batches is stable between 87% and 89%, which is higher than the industry average of 82%. The number of fish fillets per pack is 100% consistent with the marked quantity, and there is no case of insufficient quantity. For the individual batches with slight fluctuations in yield rate, the R&D team has immediately adjusted the pre-processing parameters (including the time of the quick-freezing process and the concentration of the marinade) according to GM Zhao's suggestions, and will conduct a follow-up verification test tomorrow.

Ms. Li, the Quality Control Director of Hongjia Food, said: "The personal supervision and follow-up by GM Zhao have greatly boosted the team's confidence in quality improvement. This round of in-depth testing not only verified the stability of our products but also provided precise data support for process optimization. We will take this as an opportunity to further refine the quality control standards and implement stricter process supervision."

The entire process from yesterday's on-site inspection to today's follow-up suggestions and in-depth testing reflects Hongjia Food's closed-loop quality control philosophy. Unlike the traditional "inspection-only" model, Hongjia Food has established a complete quality management system that integrates "inspection-discovery-optimization-verification". Every inspection result is transformed into a driving force for product improvement, and every optimization measure is verified through iterative testing to ensure that the product quality is continuously upgraded.

GM Zhao summarized after the testing: "In the food industry, quality is not a static standard but a dynamic pursuit of excellence. For Hongjia Food, every product leaving the factory is a commitment to consumers. By adhering to the closed-loop quality control model, we can promptly identify and solve potential problems, ensuring that our products are always at the forefront of the industry. In the future, we will continue to maintain this proactive attitude, regularly carry out in-depth product testing, and bring safer, more reliable, and more consistent high-quality products to the market."

This follow-up testing and optimization work not only further consolidated the quality advantage of Hongjia Food's Pre-Marinated Snakehead Fish Fillets but also set an example for the entire processed aquatic product industry. With such a rigorous quality control system, Hongjia Food is expected to further enhance its market competitiveness and win more trust from consumers and partners at home and abroad.

Hongjia Food Co., Ltd. is a professional enterprise integrating the production, processing, R&D, and sales of aquatic products and semi-prepared dishes. Adhering to the core philosophy of "Quality First, Consumer-Oriented", the company has built an advanced production base, a professional R&D team, and a comprehensive closed-loop quality control system. Its flagship product, Pre-Marinated Snakehead Fish Fillets, is popular among domestic and foreign markets for its excellent quality, convenient use, and stable taste. The company is committed to promoting the upgrading of the processed food industry and providing safe and healthy food solutions for global consumers. For more information, please get in touch with us.

No.48 East Ring Road,Mizhou Street,Zhucheng City,Weifang City,Shandong Province,China.